CONCRETE POLISHING

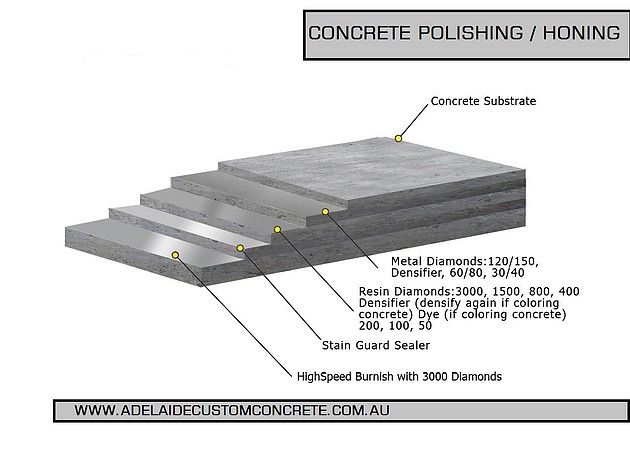

Polished concrete is a mechanical grind and polish process that utilizes industrial diamonds & impregnating hardeners and sealers to level, densify, polish, and seal concrete floor. Polishing brings out the natural beauty of concrete by smoothing the surface.

In addition to its extensive life cycle and cost efficiency, polished concrete floors offer a number of benefits. Multiple grinding stages smooth concrete to a smooth high luster finish.

Your options for polished concrete are the level of aggregate you would like to expose, a light, medium or full grind will decide how much grinding will need to be done and therfore also change the price per square meter rate. After the grind is completed we can then go to the level of gloss required.

Available for outdoor concrete surfaces.

SURFACE FINISHES

CREAM

Enhances the natural beauty of the concrete. This process simply polishes

the cream at the top level of the concrete not exposing any of the sand or aggregate. This finish leaves a smooth sealed surface which is easy to

clean and maintain. Cream polished concrete finishes can range from low

gloss matte to a high gloss mirror finish

GRIND & SEAL

Grind and Seal is machine grinding to the desired exposure followed by

a Surface Sealer in either Acrylic or Polyurethane to give the concrete

a matte or gloss look. This the most affordable option Also available

for outdoor concrete surfaces.

SALT & PAPPER

Starts with grinding to expose the sand in your concrete.

The polishing enhances the beauty of the concrete’s sand exposure

with finishes ranging from low gloss matte to high gloss mirror finishes.

FULL & EXPOSURE

Starts with heavily grinding to expose the natural or seeded

aggregate in your concrete. This beautiful finish can range

from low gloss matte to high gloss mirror finish.

CONTACT TODAY FOR FREE QUOTE

Honed Concrete

Honed Concrete is an ideal solution for outdoor concrete flooring. Honed Concrete follows the same recipe, but instead of washing away the rough surface and applying the polish,

it is ground down with a concrete machine to reveal the aggregates and stone usually finished with a penetrating sealer giving the concrete a more natural look

To get a free quote, or to book an inspection

- Woodville South SA 5011, Australia

-

Open : Mon - Fri 8 AM - 5 PM ,

Sat 9 AM - 2 PM - info@adelaidecustomconcrete.com.au

- 0403 296 238